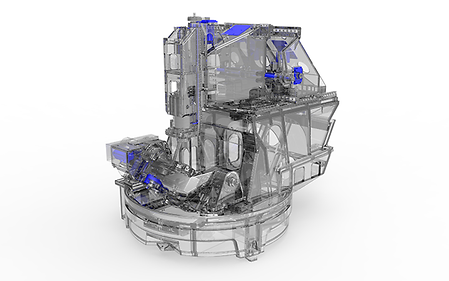

ULTRASONIC 65 2nd Generation

ULTRASONIC machining centre in reliable monoBLOCK design

Max. X-axis stroke

29 in.

735 mm

Max. Y-axis stroke

26 in.

650 mm

Max. Z-axis stroke

22 in.

560 mm

Max. workpiece diameter

33 in.

840 mm

Max. workpiece height

20 in.

500 mm

Max. workpiece weight

2,205 lbs.

1,000 kg

Control & software alternatives

SIEMENS

Highlights

ULTRASONIC technology integration - reduced process forces for higher productivity

- Technology integration via HSK-A63 interface for ultrasonic superimposition of the tool rotation with amplitudes up to 15 µm

- Process forces reduced by up to 50% through ULTRASONIC enable, depending on requirements: higher feed rates, improved surface quality up to Ra <0.1 µm, longer tool life

- Specific coolant treatment systems with centrifuges, optimized for the ULTRASONIC processing of Advanced Materials

ULTRASONIC 3rd Generation - Optimal process control through intelligent controls

- Constant amplitude in the process to ensure reproducibility

- Automatic detection of the working frequency, significantly improved hardware for signal acquisition

- Frequency tracking and simultaneous power control in real time for optimal process stability

- Ensuring the ULTRASONIC advantages even with non-optimal tools

- Fully compatible with 2nd generation ULTRASONIC actuator

Ergonomic

- Large door opening of 1,500 and unique access to the working area, most compact machine with a footprint of just 12 m²

- Unrestricted crane loading of up to 1,500 kg

- Quick and easy to set up thanks to it´s three-point support

Precise

- Comprehensive cooling measures, high-performance coolant unit and multi-sensor compensation as standard

- From 5 µm positioning accuracy in standard

- Stiff construction with high static masses and balanced moving parts

Versatile

- Several table solutions from the 5 axes machining with up to 1,500 kg or complete machining with milling and turning with up to 2,050 Nm

- Widest spindle range on the market with up to 30,000 rpm or with up to 430 Nm

- Machine integrated tool magazines with up to 180 pockets

Stiff monoBLOCK concept

- monoBLOCK – Maximum stability from one casting

- One-piece column with large, stable slideways, 55 mm roller guideways in all axes

- Maximum stability thanks to large ball screws in all axes ø 50 / 50 / 50

- FEM optimisation of all components

- Clamping of the swivelling rotary table

Application Examples

Automation

Standard automation and customized solutions in the VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customized automation solution for flexible manufacturing systems: