Additive Manufacturing Consulting

With its consulting approach, the DMG MORI Academy pursues the goal of supporting companies in developing the required design know-how and establishing the process chains around the LASERTEC DED and LASERTEC SLM series. The consulting portfolio includes services along the entire process chain of additive manufacturing, including the AM Quickcheck as a perfect entry point for exploiting these potentials. In a two-day workshop, experienced DMG MORI engineers support companies in the industry-specific and needs-based introduction of the technology.

Overview

Start now and use the full potential of the SLM technology!

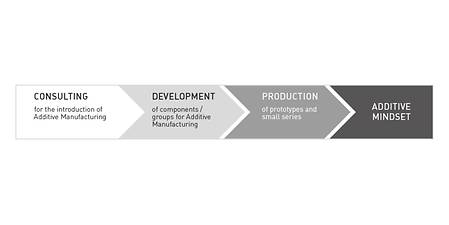

The DMG MORI Academy supports companies with the introduction and use of Additive Manufacturing with a new comprehensive portfolio.

Our services

- Additive Manufacturing Quick Check for the identification of your specific Additive Manufacturing components

- Redesign of your components for Additive Manufacturing

- Engineering and design of new components and groups

- Simulation and topology optimization

- Production of prototypes and small series of your components

- Courses and training for management, design and manufacturing departments

- Consulting for the strategy from design optimisation, through to your Additive Manufacturing production

Quickcheck

Quick check as the perfect start for your design

2-day on-site workshop at the customers

Aim: Development of basic knowledge and identification of components with Additive Manufacturing potential.

Benefits

Customers recieve practical knowledge in Additive Manufacturing based on many examples. The first components with Additive Manufacturing potential are also identified and analysed. Participants thus learn to identify the right components for Additive Manufacturing for the future.

Target group

The Additive Manufacturing Quick Check is intended for developers and design engineers. Production planning and preparation are compimentary to this process.

Design for Additive Manufacturing

Additive Manufacturing requires innovative thinking in design. We help your development team to the next level!

Best Practices

Training Offer

Construction training courses

Design for Additive Manufacturing Basic Previous knowledge: CAD basics

Design for Additive Manufacturing Advanced Previous

Knowledge: Basic training

Duration: 4.5 days each

Number of participants: Max. 8 persons

Target group: Specialists and executives in the area of development and construction

Course start: Ongoing, several times a year

We help you with the technology introduction!

Contact:

Dr. Rinje Brandis

Head of Consulting Additive Manufacturing

Phone +49 5205 74 2575

rinje.brandis@dmgmori.com